rúllu

shapeshifter. groundbreaker. nap-taker.

the least danish thing made in denmark.

danish design principles include tradition and reduction, improving on the good, reducing for minimalism. rúllu doesn’t have a starting point, or an ending point. there is no predecessor to improve on, there is only the next iteration.

practical skills

contributors

collection

leatherworking

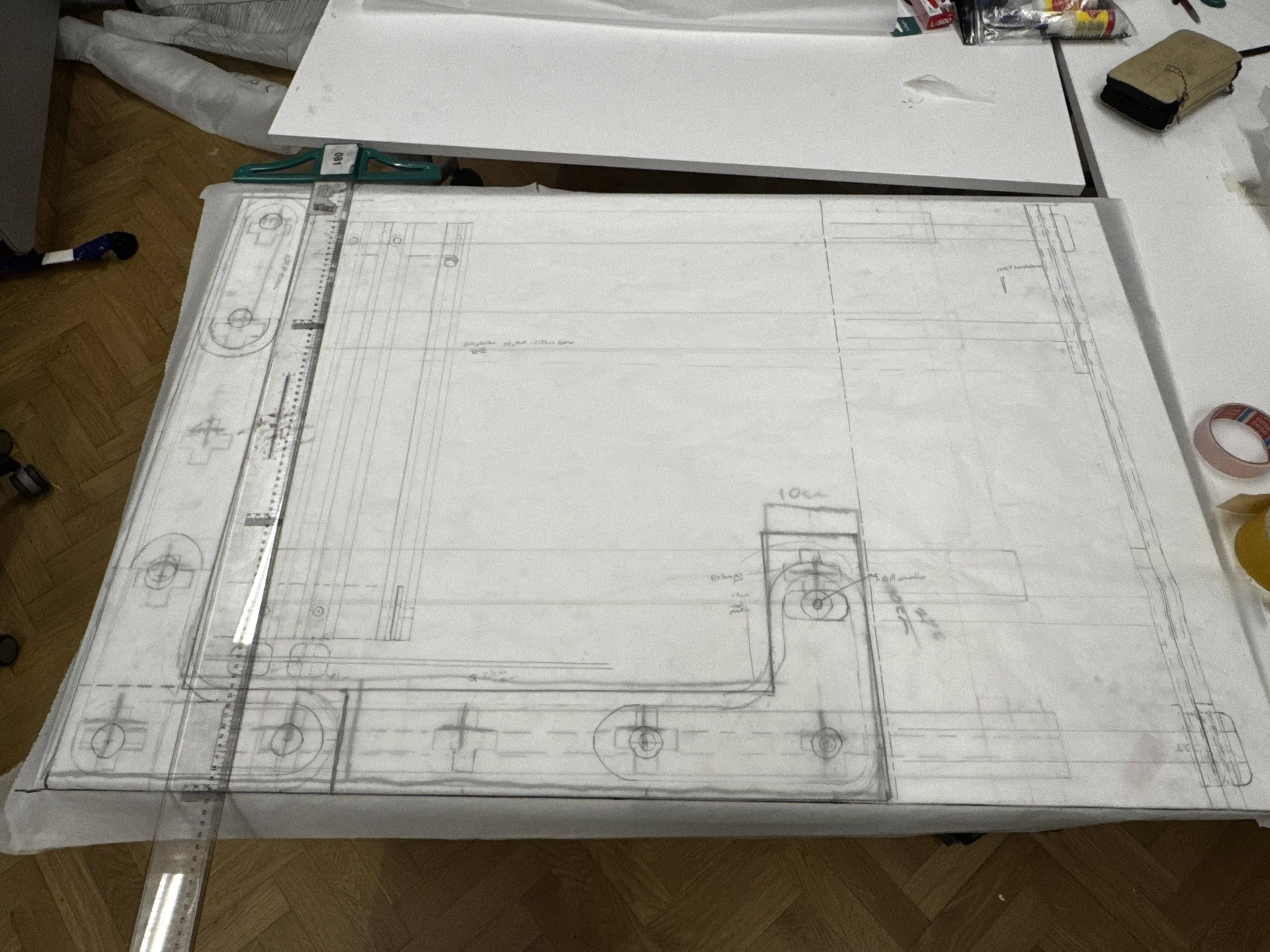

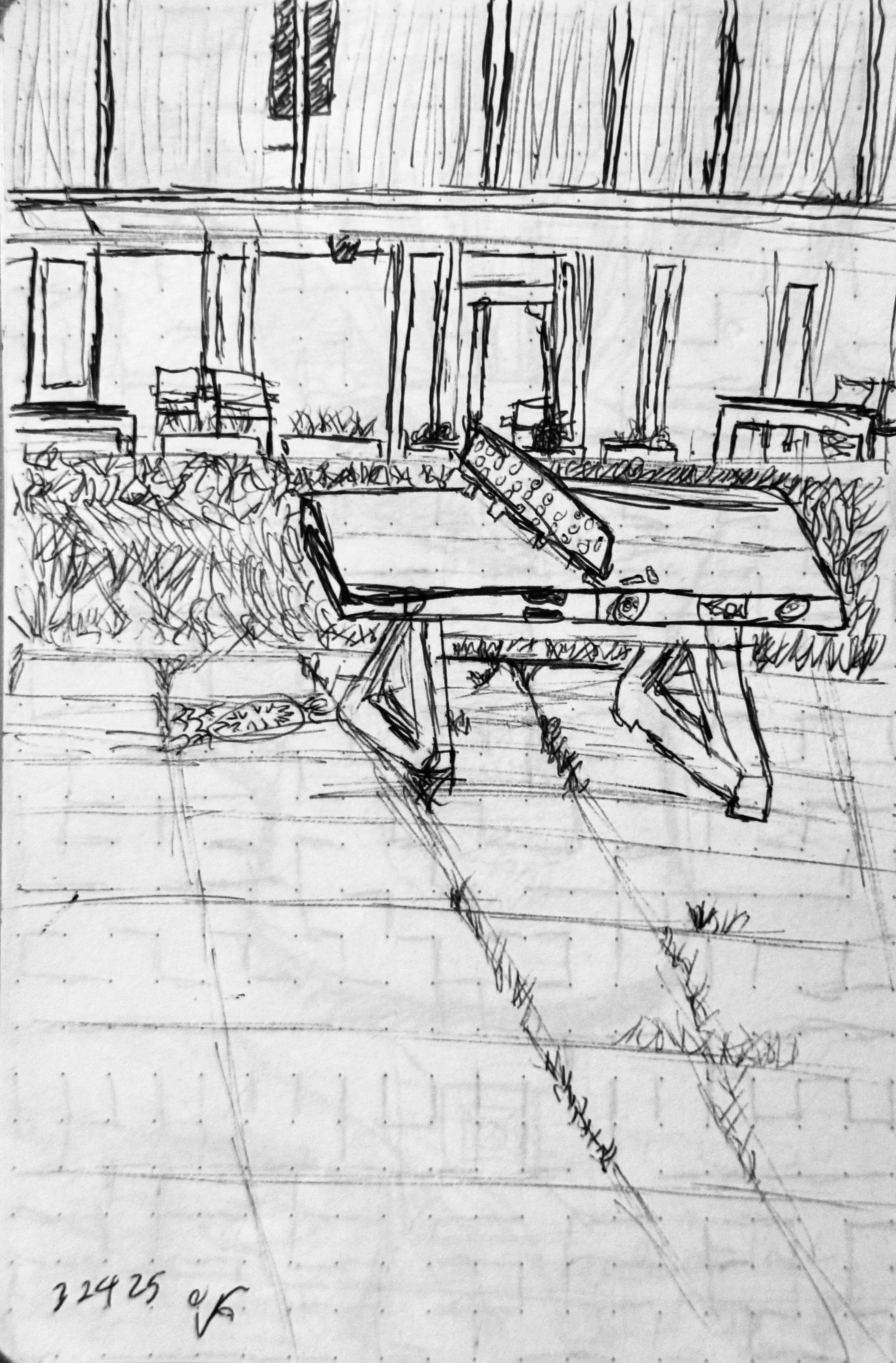

iterative sketching

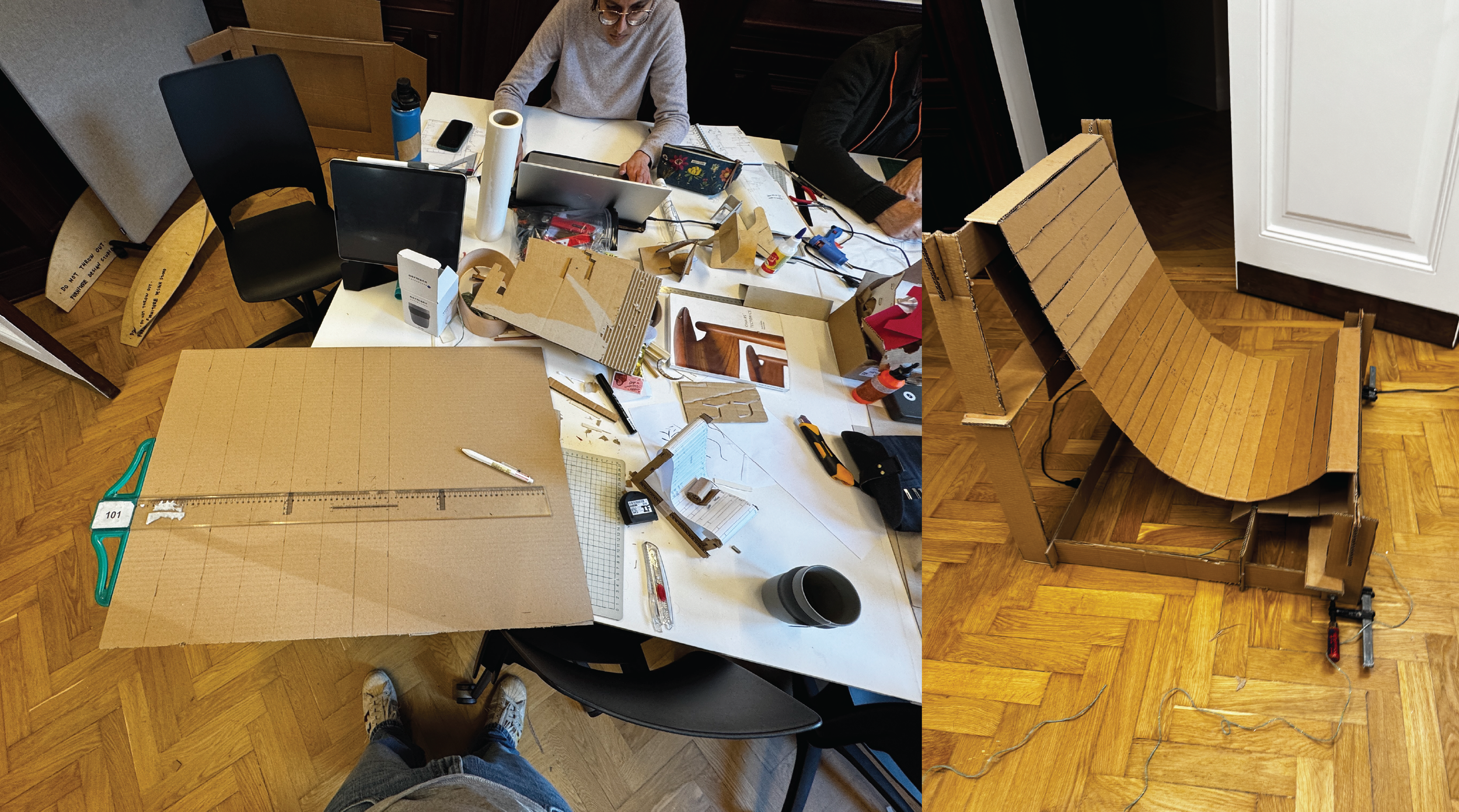

modelmaking

human factors

bokeh furniture lab

generative ai disclosure.

openai’s chatgpt 4o generative ai model was used in this project for:

information gathered on human spine anatomy ergonomics for slat width and spacing.

iterative critique on mechanical aspects & proportional dimensions.

artificial intelligence was not used in any capacity for creative decision-making or concept generation.

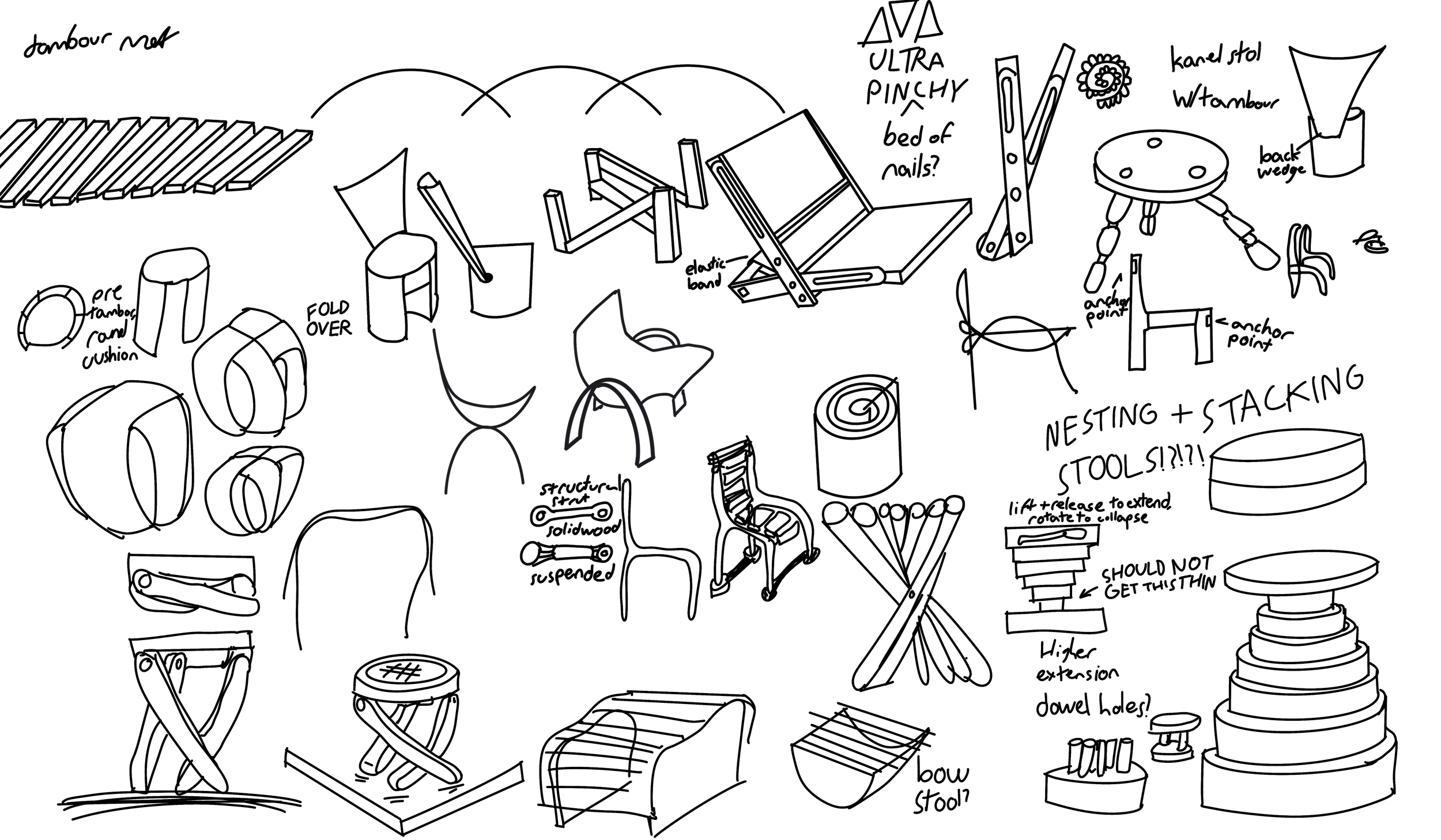

now this. now that.

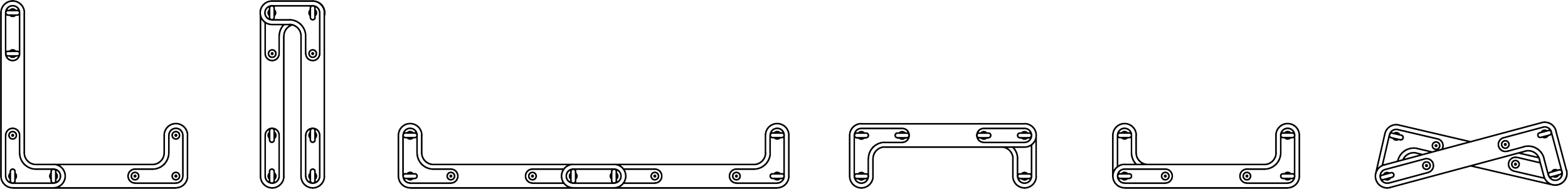

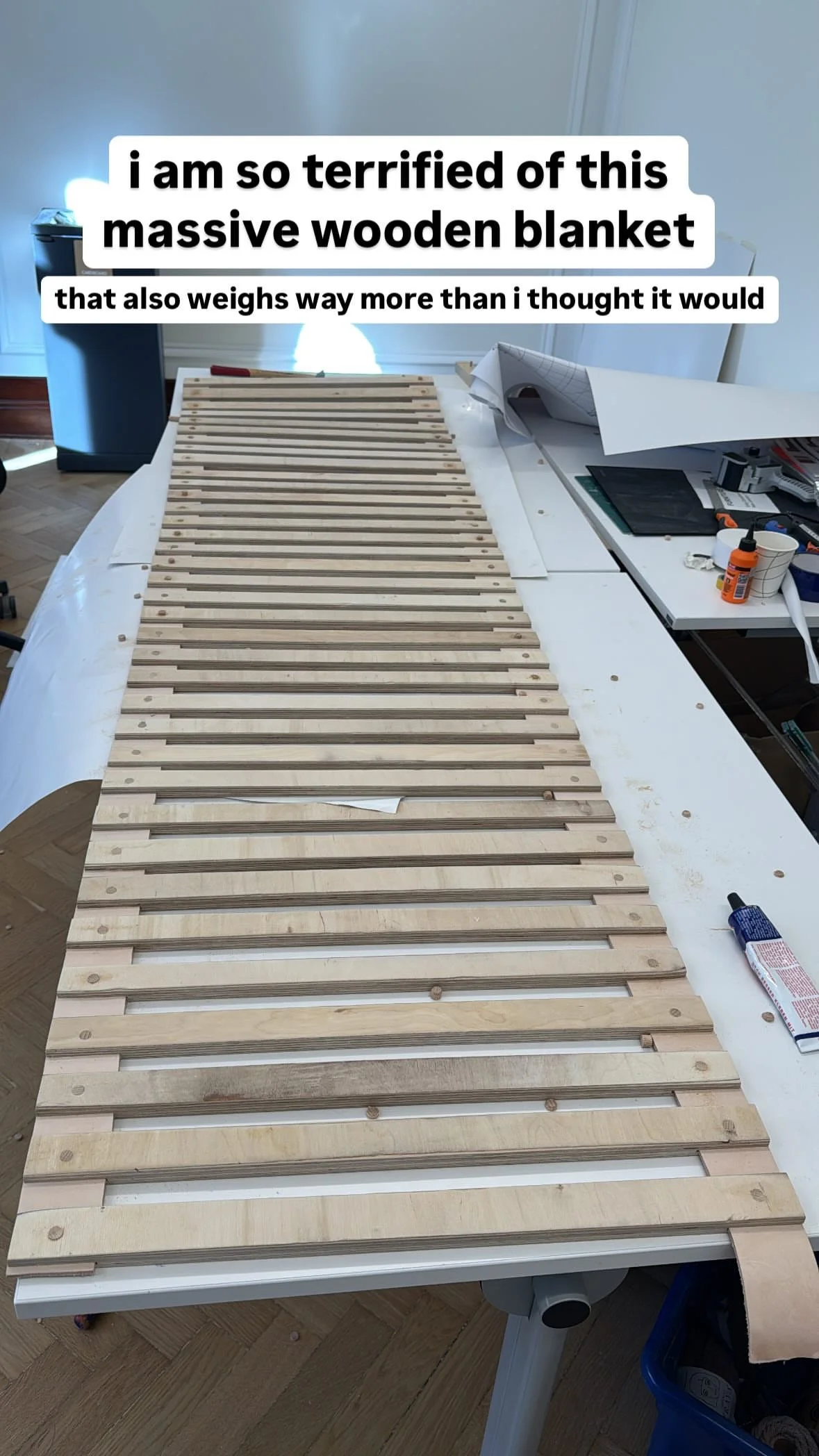

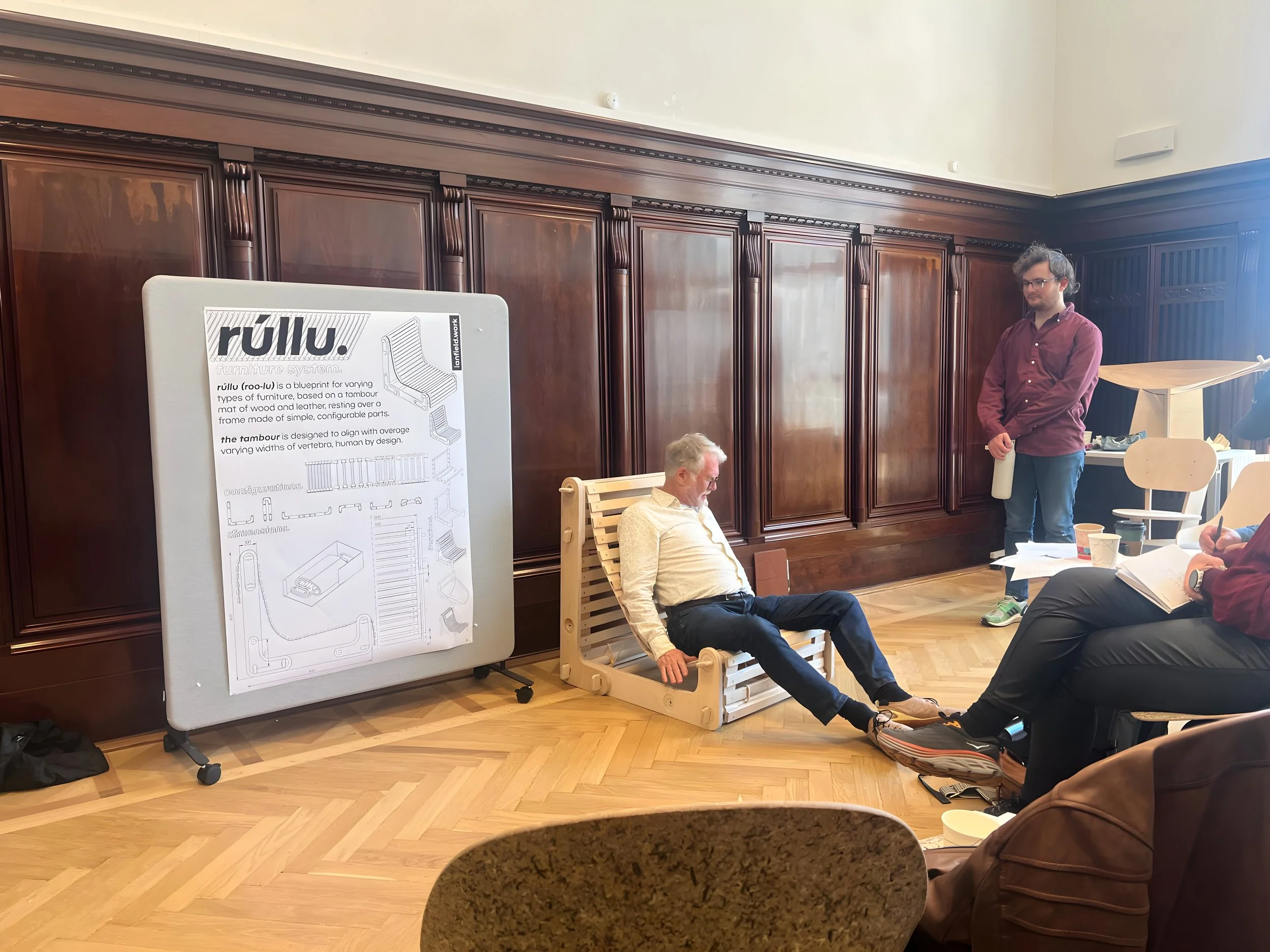

rúllu’s “l-frame” construction and tambour enables countless forms of furniture, swappable between forms in 5 minutes or less. forms range from a lounge to a daybed to an armchair, all with the same parts and construction method.

how many forms can rúllu take? the answer is unknown. when reconstructing the chair, it invites new form experimentation based upon the same principles of suspension and configuration, with the tambour itself being usable as a floor mat or beach blanket.

a chair in suspense.

a furniture project doesn’t truly start until it’s called “ambitious” or “bold”. some say that i seek this reaction. those people could not be more correct. if there’s a doubt in a product’s probability of existence, that’s where i begin.

rúllu wasn’t constructed until the night before our final critique, and even after then tensions were high. all of these puns are intended.

again. and again. and again.

if i said any of my ideas made sense at the start, i was lying. before the current (8th) iteration, there were roughly 20 different directions. rúllu is not anywhere near a “finished” state, but is a show of perseverance for the unusual and experimental.

rúllu, in it’s state is more of a proof of concept (and comfort). there are staggering amounts of improvements and optimizations to be made in almost every way. which makes it both an exciting and arduous project to revisit.

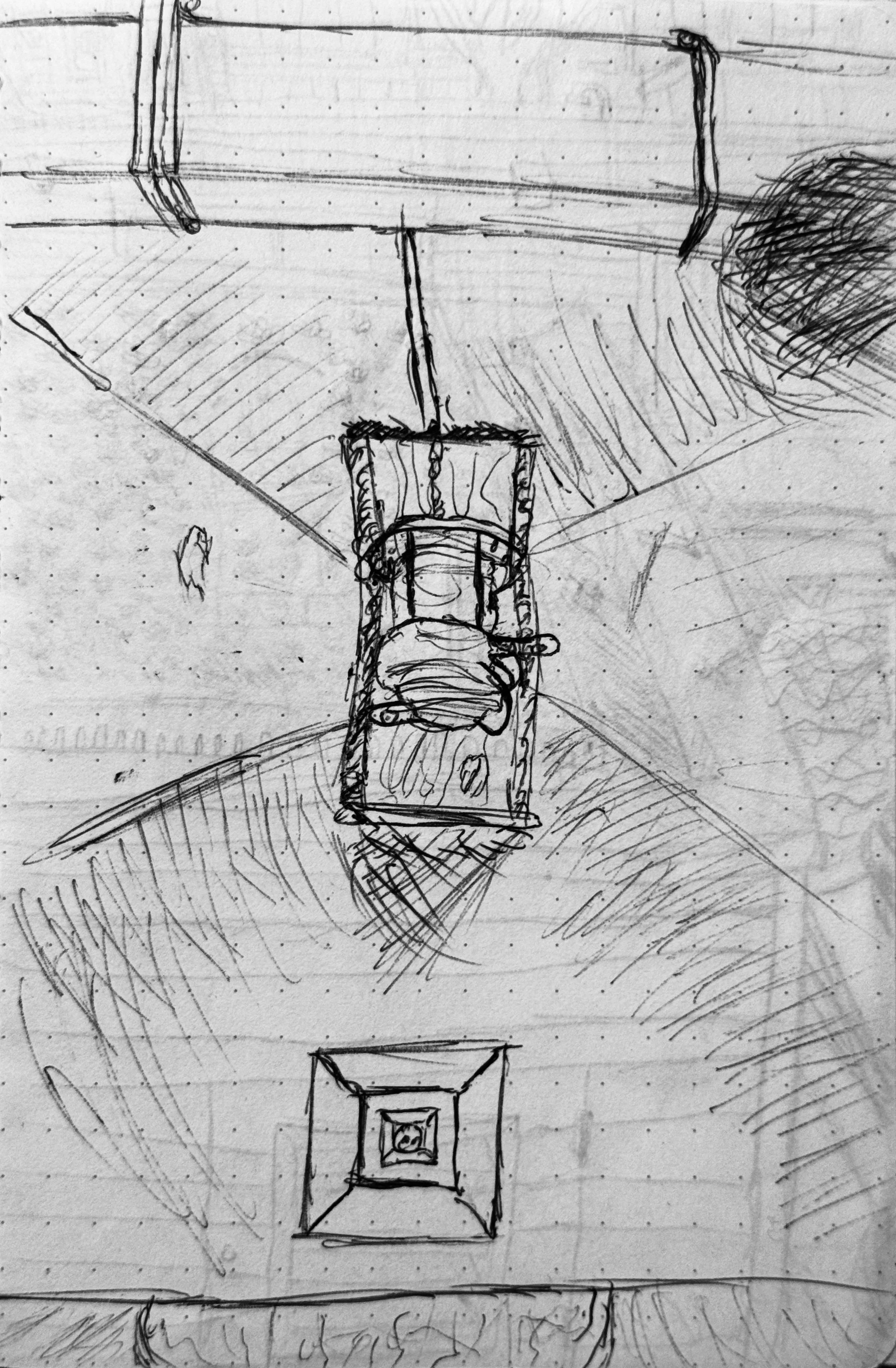

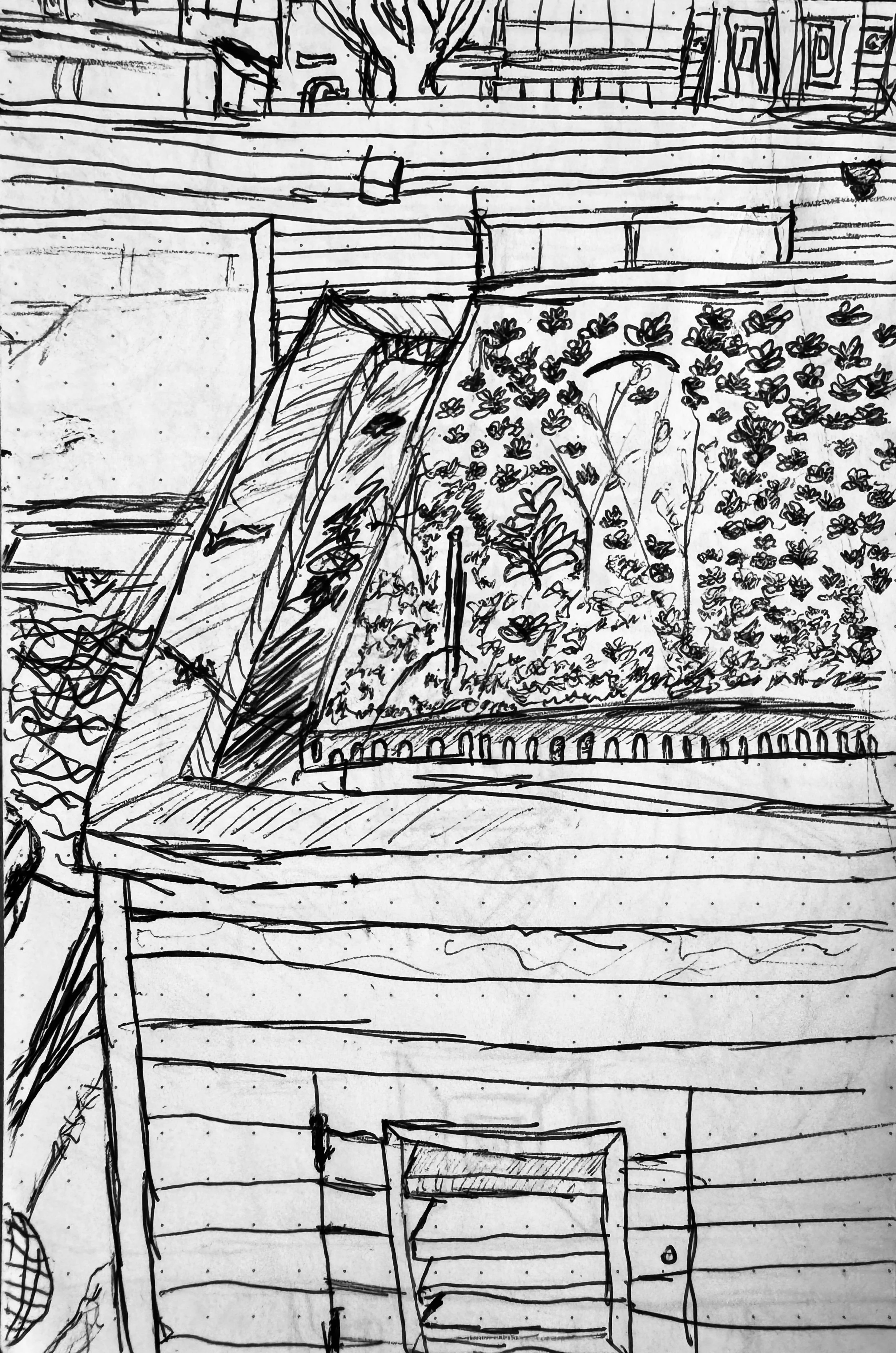

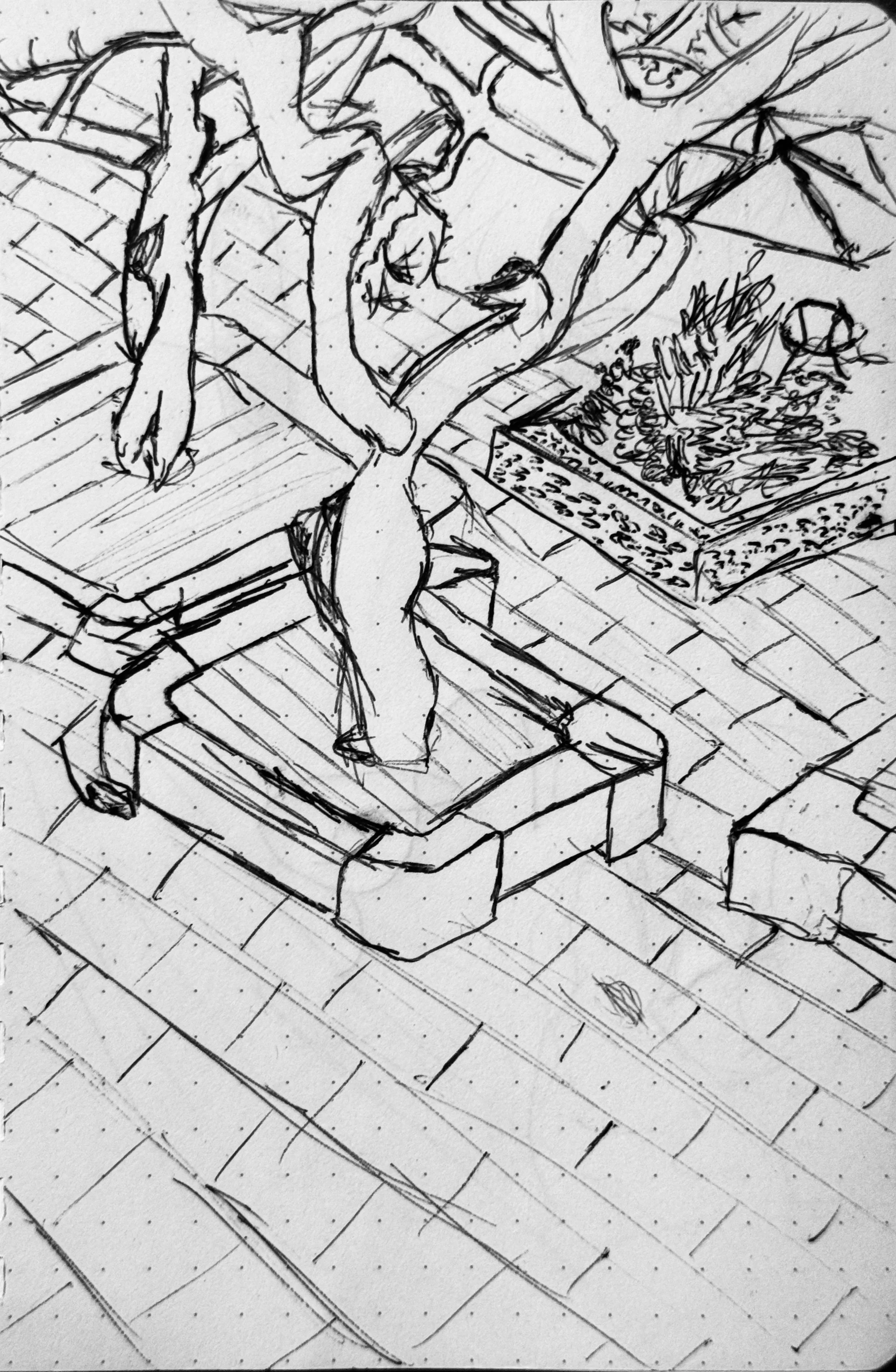

processwork.

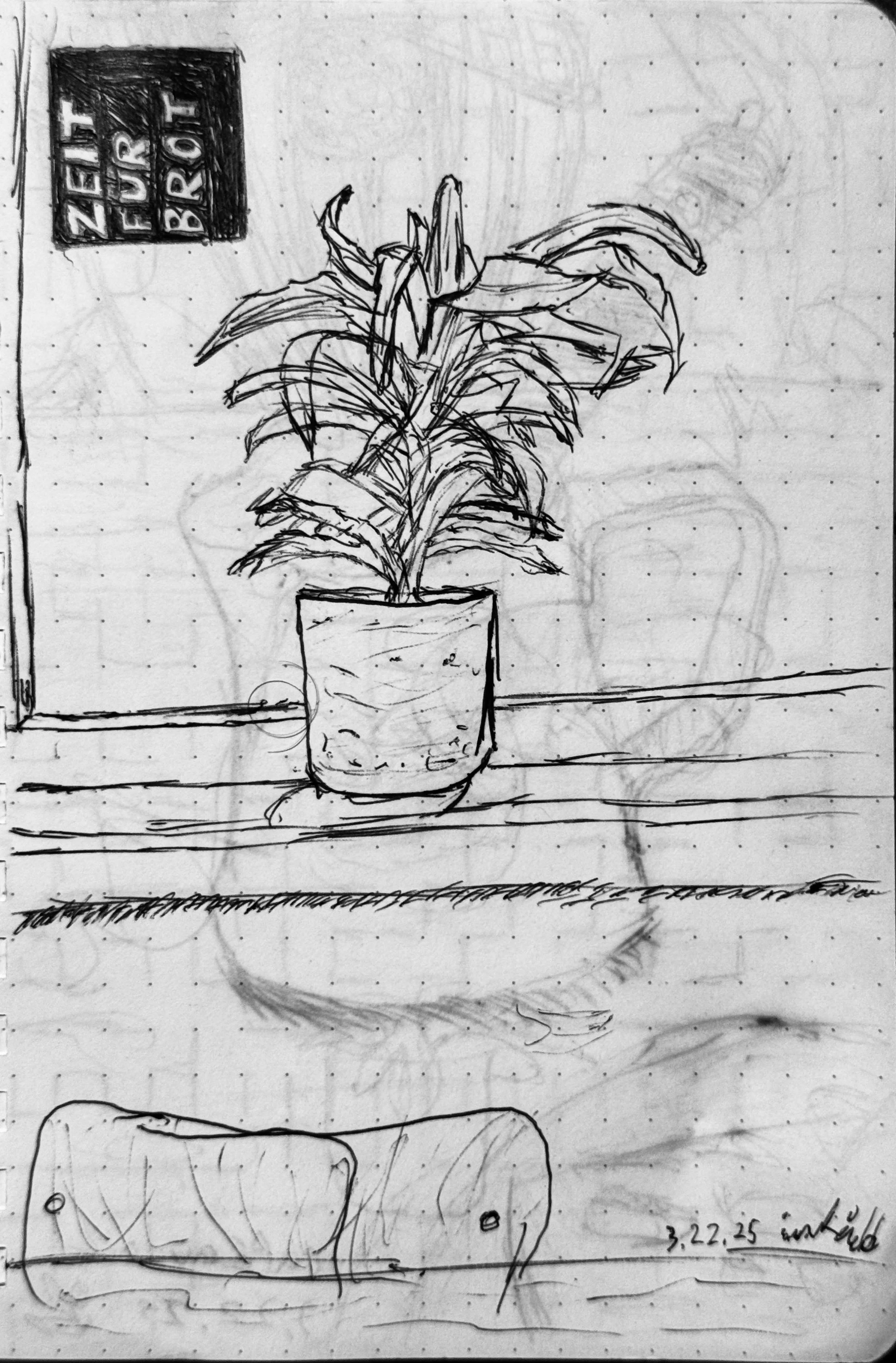

notepad still-lifes i captured during my travels, as an epilogue, this image represents what was so special about copenhagen.

special thanks to erin earthman and lucy mauries for letting me use this photo and their support of me throughout the semester.

image taken at floss bar - larsbjørnsstræde 10, 1454 københavn, denmark.

wall art by @theworkofscott.